As one of the leading manufacturers of recycled Polyethylene Terephthalate (rPET), Al Mehtab Industries understands how environmentally-sound decisions can impact the packaging bottom line.

But what exactly is PET? And why is rPET so valuable?

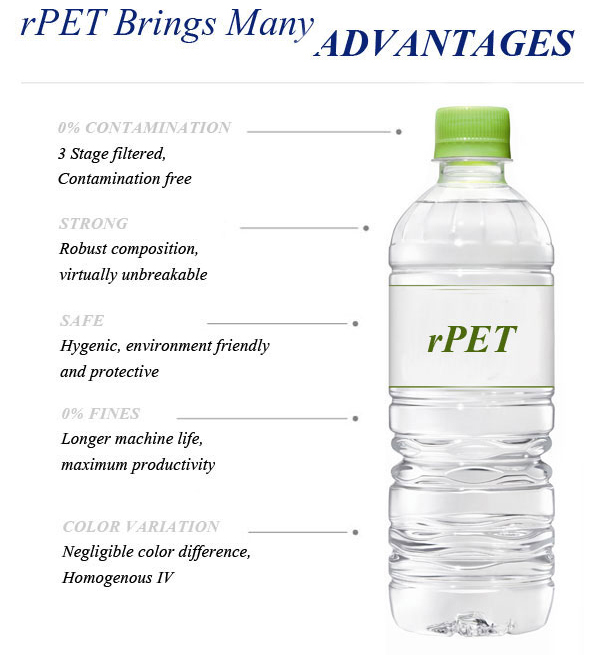

|

PET is a polymer that is used to manufacture strong, clear, bottles, lightweight containers and packaging. A key advantage of PET is that it has a well-established recycling infrastructure and can be recycled numerous times. Its superb physical properties enable the manufacture of lightweight containers which minimizes the use of natural resources. Through Al Mehtab’s ongoing focus on process and product development, we’re able to develop cost-effective, high-performing rPET resins. They provide our customers with a sustainable resource which helps them meet regulatory mandates for both food and non-food applications. Through our state-of-the-art materials separation and elutriation services, we also can take your scrap regrind, re-melt and reform it into pellets that can be reintroduced into your bottle-making process. |

Sustainable resources, attainable solutions

By creating clean, high-quality rPET in a consistent manner, Al Mehtab rPET resins can easily be incorporated into packaging for a variety of applications.

Using modern technology, Al Mehtab is able to pelletize and crystallize recycled, post-consumer PET for reuse back into consumer packaging applications. State-of-the-art processes and quality assurance standards have enabled the company to develop rPET that can be blended with virgin resin and actually mimic its performance.

Additionally, rPET requires less energy to manufacture per pound than that of virgin PET. The end result is a sustainable, cost-effective, high-performing solution that many of our customers use as a 100% replacement for virgin-without compromising manufacturing efficiencies or product performance standards.

Implementing innovation, maximizing value

Using the process, we’re able to pelletize and crystallize rPET for reuse back in to consumer packaging applications. Always at the forefront of recycling innovation, the process enables us to produce rPET that processes like virgin PET but requires less energy to manufacture. And since it runs like virgin, no special process changes are needed to use our rPET.

With advanced technology, innovative quality processes, cost-saving repelletizing services, and first-rate support, Al Mehtab Industries can exceed your expectations – and maximize your profits.